Khavar Vacuum Packaging Industries

Our Services

The best chose us

Our products

Greetings, welcome to Khavar Vacuum Forming Industries website.

In the following, we have collected information about “Vacuum Forming Packaging” for you and we intend to examine this topic in a specialized manner.

We hope that this content will be useful for you dear ones, so that you can make the right decision in choosing the right packaging for your product.

Stay with us…

Table of Contents

Vacuum forming

By the grace of God Almighty, Khavar Vacuum Forming Packaging Industries has more than 20 years of successful experience in the field of providing packaging services and manufacturing vacuum forming machines and devices.

Khavar Vacuum has been able to take a successful step in the packaging and production industries of our country with experienced employees and up-to-date and advanced equipment as well as the combination of creativity and technology.

Vacuum forming is one of the oldest and best ways of processing plastic materials. The products that are designed and produced with this method are always related to us and play an important role in our daily life.

One of the methods of processing plastic materials in the field of vacuum packaging is vacuum thermal forming or vacuum forming, which Vacuum Forming Industries uses this method in providing packaging services.

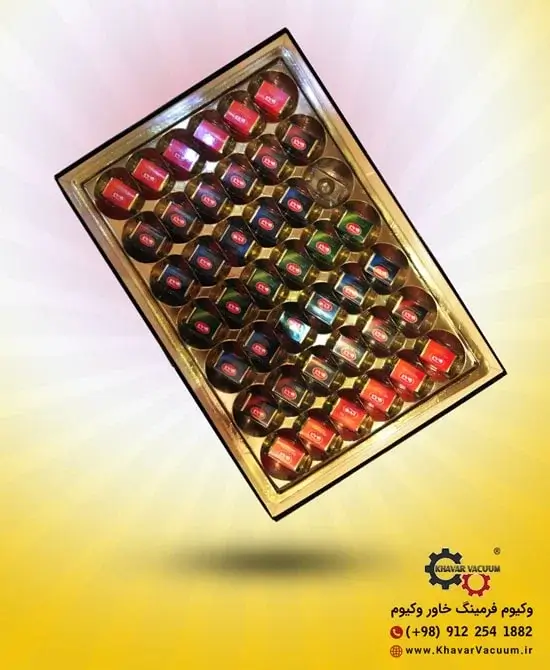

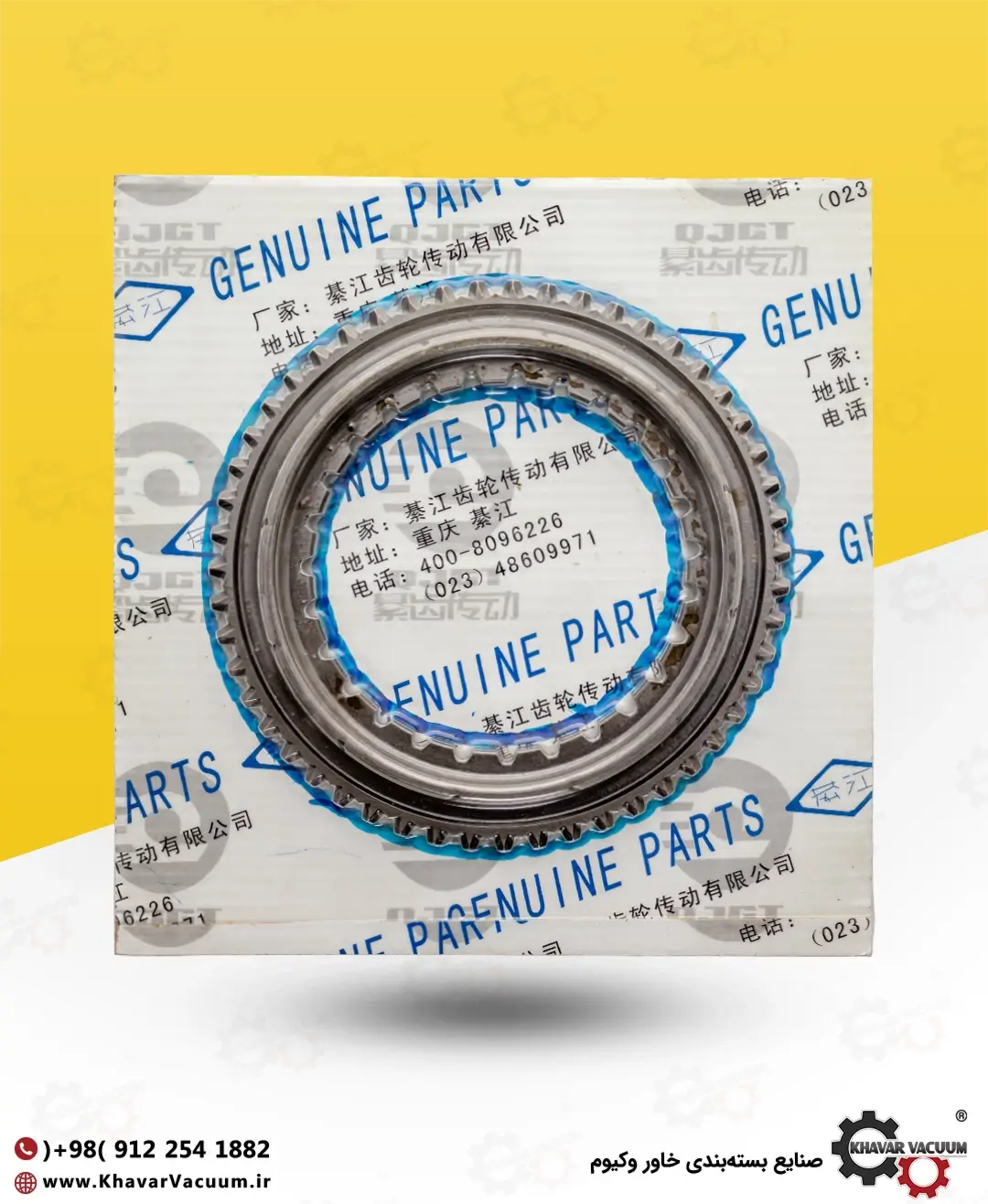

Vacuum forming packaging is one of the best methods for packaging products such as cosmetics, tools, food, sweets and chocolates, electronic products, toys, car accessories, etc. Many plastic parts from disposable containers to egg packaging and the like are produced by this method.

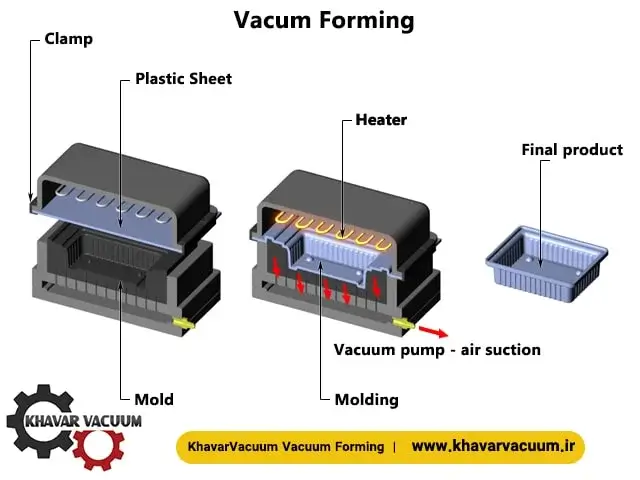

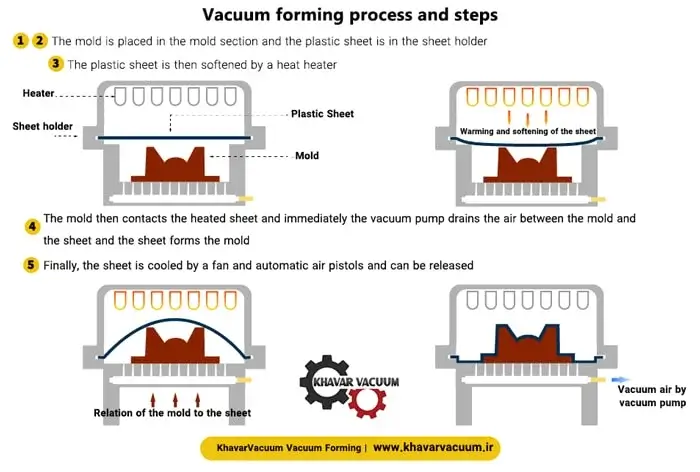

Vacuum forming is a process that, during certain stages, first sees a transparent plastic sheet (thermoplastic) until it becomes soft and flexible, with a special heater.

In the next step, the vacuum pump evacuates the air between the sheet and the aluminum mold by creating negative pressure through suction.

Then the heated plastic sheet sits on the cold mold, finally the plastic sheet cools and hardens and takes the shape of the mold.

Vacuum forming packaging is very affordable!

Because it is a very low-cost, easy, widely used process with high power and speed in the production of transparent plastic parts for packaging, and there is no substitute for this technology!

One of the main advantages of vacuum forming is high speed and power in production, so that there is a small gap between production and product supply, and its cost is significantly cheaper compared to injection molding.

Types of vacuum forming packaging

Card vacuum packaging

This type of packaging is the most widely used and is used for packaging consumer goods such as toys, children’s items, tools, electrical appliances, etc.

In this type of packaging, a cardboard sheet, which is usually printed, is placed between the shaped plastic (PVC) shell, and a hole is usually made above it so that it can be hung in the store.

Sliding card vacuum packaging

This type of package also includes a vacuum piece and a cardboard card, the cardboard card is placed slidingly inside the vacuum piece.

Pressed card vacuum packaging

This type of package also includes a vacuum piece and an adhesive cardboard card, which the vacuum piece is pressed on the cardboard card with a press machine.

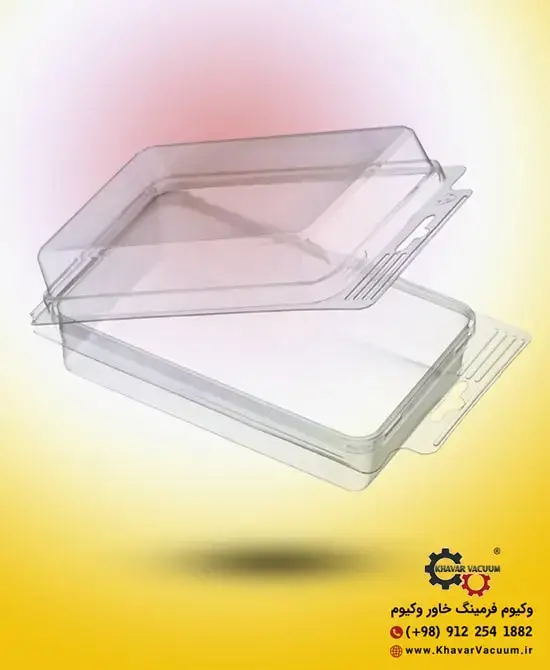

Clamshell vacuum packaging

Shell or folding packaging is a type of packaging that uses a one-piece hinged container to store different products. This type of packaging is mostly used for food products such as beans, dried fruits, fruits, etc. Of course, in some cases, card-fold packaging is also used for product packaging.

Advantages of vacuum forming packaging

This process has many advantages, some of the most important ones are:

Provide a clear and visible product

The packaging of vacuum forming is transparent and this feature makes the buyer to view and check the product while buying and then proceed to purchase.

Being affordable

Due to the use of relatively simple and low-cost equipment, and the use of low-cost plastic materials and the recycling of waste from the final product, it is a cost-effective process.

Saving time

This process is the fastest way to process plastic materials and it is one of the fastest methods in terms of design and production time.

Detailed design and implementation

The products and parts produced by this process are much more accurate and suitable compared to other methods.

Flexible design

In this process, by using the design of the mold before production, the prototype of the product can be examined from every point of view and the design can be changed if needed.

High production capacity

This process has high speed and power due to the use of integrated plastic sheet and continuous production.

Applications

Packaging Industry

Vacuum is used for packaging toys, electronic devices, cosmetic-sanitary products, sweets and chocolates (vacuum stand), packaging of medicine and medical supplies, food and production of disposable containers.

Agriculture

It is used to produce seed planting trays, pots, small dome greenhouses.

Medical and hospital industries

Vacuum is used to produce medical trays, ampoule packaging and medicines.

Home and kitchen appliances

Spoons and forks, containers and kitchen storage containers.

Panel making

Production of prominent letters and shapes in panel making.

Electronics industry

Production of housing and protection for electronic equipment, production of antistatic trays.

Vacuum forming process

Consultation, design and mold making

In the process of vacuum forming, consultation should be done first to determine the specifications, type of plastic sheet and the size of the piece or package. Then, according to all these things, the mold is designed and made. Molds are often made of aluminum and are made with a CNC machine.

Place the template

First, the desired mold is placed in the mold part of the vacuum machine, and then the plastic sheet is placed in the machine’s sheet holder.

Placing sheet or film

Here, the plastic sheet, which is made of PVC, HP, PET, ABS or Hempack, is placed in the sheet holder. The sheet holder must be strong enough to ensure that the plastic sheet is held firmly during the forming process. And then according to the thickness of the plastic sheet (6 mm or 10 mm) it should be heated properly.

Heating

Then the plastic sheet, by a heater installed on a plate above the sheet, sees enough heat to become soft and flexible. In order to achieve the best forming result, the entire surface of the plastic sheet should be heated uniformly and properly.

To achieve this goal, temperature and heating duration regulators must be available in our device. For thick plastic sheets, high heating and powerful heaters are required.

Vacuum forming

Once the plastic sheet is properly heated, it is ready to be shaped and molded.

At this stage, the cold mold comes into contact with the heated and flexible sheet and immediately the vacuum pump evacuates the air between the sheet and the mold. Then the sheet sits completely on the mold and takes the shape of the mold.

Cooling and release (foot)

After forming, the plastic sheet must be cooled before being released by the coolant. To speed up this step, there are fans and automatic air pistols that are used after the formation is completed.

After cooling, the sheet can be separated from the mold by feet.

Cutting, removing additions and assembling (the last step)

Once the sheet is formed and cooled, after removal from the mold, the sheet additions are cut, and if needed, other things such as punching, printing, and assembly are also applied, until the final product is obtained.

It is affordable

Vacuum forming is one of the cost-effective ways for packaging, because the equipment used in this process is not particularly complicated and relatively low-cost.

High speed and power in production

This process is the fastest way to process plastic materials and produce plastic parts for packaging, and there is no substitute for it!

Transparent packaging

This type of packaging is very honest! In fact, packaging with this process makes the customer view the product and then buy it. This feature makes the customer buy with confidence and peace of mind.

Raw materials for vacuum packaging

The most prominent raw materials used in vacuum forming packaging are PVC, PET and HP, which we will discuss briefly below.

PVC

PVC is transparent and comes in different colors, sizes and thicknesses. PVC film is less stretchy, impact resistant and cannot be metallized.

PET

Compared to PVC, PET has a higher tensile strength, PET is hygienic, and for this reason, it is mostly used in the production of cosmetic-sanitary and candy and chocolate stands. One of the advantages and differences of PET is its ability to be metallized.

HP or High Impact (HP)

HP is used for the production of disposable containers and also for the production of cosmetic-sanitary stands. HP has a good forming ability and it is possible to use fluke and velvet coating in various colors.

HP also has the ability to be laminated. In laminating, HP turns from matte to glossy.

In PVC and PET, it is not possible to use fluke and velvet coating.

The necessity and importance of product packaging

Packaging is one of the most sensitive and at the same time the most decisive stages in the supply and consumption of goods. Its importance is to the extent that it even affects the quality and content of some materials, and many consumers attribute part of the quality to its packaging. Packaging means designing and producing a container or cover for a product. The packaging should actually describe the product and by its appearance, convince the buyer about the reliability of the product.

For some companies, packaging can be a factor of differentiation from competitors and a kind of competitive advantage. An innovative packaging can even change consumers’ perceptions of the product and create a buying situation. Therefore, Khavar Vacuum Forming Industries has the ability to pack zero to one hundred products with the best price and quality in the fastest possible time, using young and expert staff and scientific and practical knowledge.

- The possibility of storing and protecting goods against chemical, physical, and mechanical factors for a long time

- Better engineering form, resulting in more layout and order

- Better performance and ease of use

- Easy transportation and reducing the possibility of damage from various environmental factors

- Easy distribution

- More sales

- waste reduction

- Helping consumers make informed purchases

- Help increase the level of income and employment

- Environmental Protection

For a better understanding of the topic and more information, refer to our articles page.

Vacuum forming machines

There are several devices used in the vacuum forming process, which we will introduce below.

The machines for producing vacuum forming parts are divided into automatic and semi-automatic, these machines do not differ much in the mechanism of vacuum forming, and the main difference between them is the amount of operator intervention and the speed of parts production.

Automatic vacuum machine

The automatic vacuum forming machine is bigger than the semi-automatic machine, it has a higher production speed and it can be said that the operator’s involvement in this machine is 20% and most of the process is done by the machine itself.

This device includes a plate holder, a mold, a heater, a cooling gun and a vacuum pump, each of which has a specific function.

The production process in this machine is such that PVC film or other thermoplastics are automatically entered from one side of the machine, and after being vacuumed and shaped, they are taken out from the other side.

Semi-automatic vacuum machine

The semi-automatic vacuum forming machine has a lower production speed because 50% of the work is done manually by the operator and it is also fed with PVC sheet or other thermoplastics.

The production process in this machine is such that the operator places the sheet in the sheeter and then the sheet sits on the mold and takes the shape of the mold, after cooling the formed part is separated from the mold.

Hydraulic heat press machine

This machine has the ability to press Talaq on cardboard with blister glue. And it is used for vacuum packaging of cards and press.

The way the press machine works is that it sticks the blistered adhesive cardboard to the plastic sheet with press pressure and heat.

The heat and stroke (the height of the press plate) can be adjusted and the dimensions of the working plate of the machine are 50 x 50 cm.

This machine is completely safe, does not cause noise pollution and does not cause any problems to work in semi-residential places, and the pressing power of this machine is from 2.5 to 6 tons.

Frequency welding machine

This device has the ability to weld and glue two layers of PVC to each other. And it is mainly used for vacuum card packaging.

The way this device works is that it glues two layers of PVC to each other with frequency using a copper or aluminum mold.

In this process, the greater the thickness of the coating, the power of the machine should be increased.

Screw compressor

The screw compressor device is used to supply compressed and uniform air and has various uses in industrial units.

This device is used in the vacuum forming process to cool the molds and improve the performance of the jacks, and it is also used for footing, cooling and separating the vacuum part from the mold.

Rotary vacuum pump

This device is used to create vacuum or negative air pressure.

The rotary pump has a significant application in the vacuum forming process, in fact, it is used to evacuate the air between the mold and the vacuumed part.

The function of this device makes Talaq adhere to the mold properly and forming in vacuum forming is done with the help of this device.